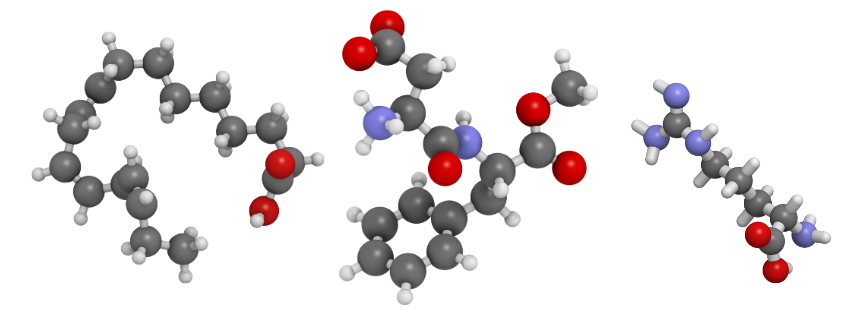

A plastic recycling machine is a powerful tool designed to convert plastic waste into new raw materials. These machines utilize various processes to transform discarded plastics into reusable materials, playing a crucial role in environmental preservation and resource conservation. In Iran, this industry is one of the most profitable sectors, with recycled granules being exportable to many countries.

Types of Plastic Recycling Machines

-

Plastic Shredder: This machine cuts plastic waste into small pieces using sharp blades.

-

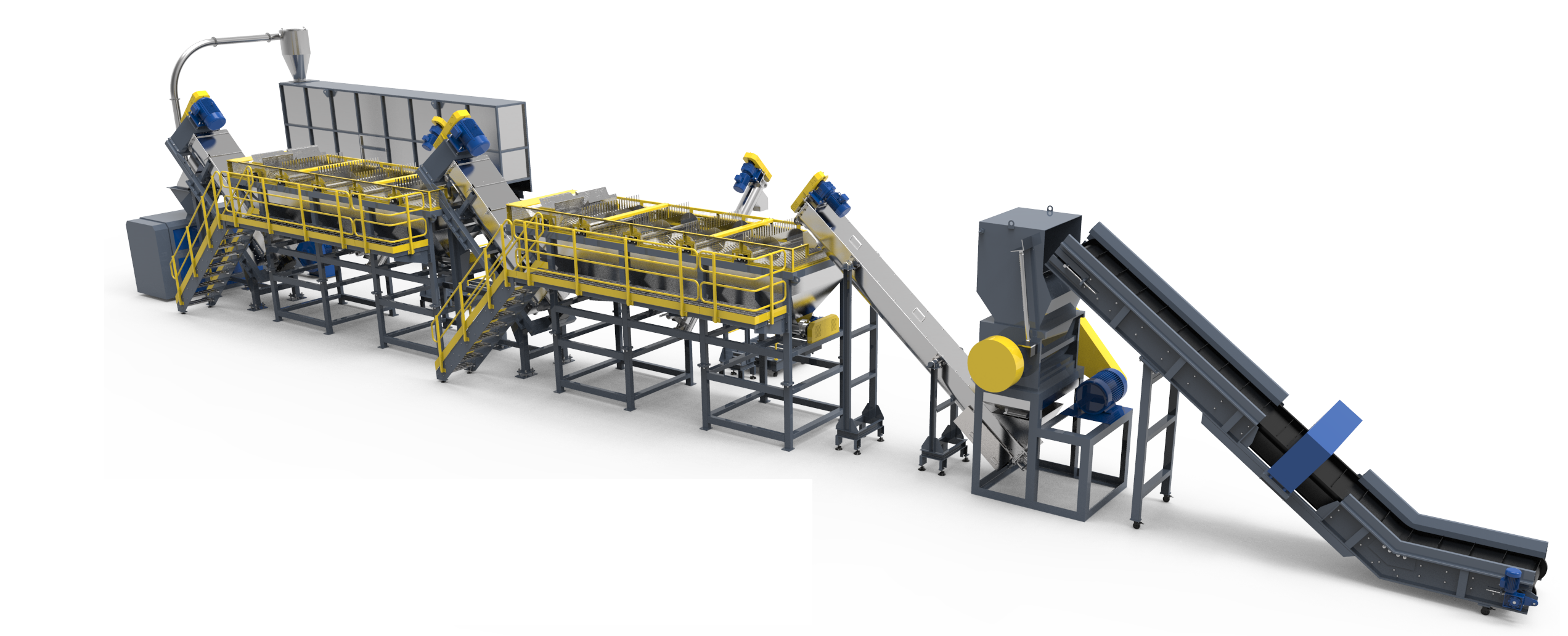

Plastic Washing Machine: In the first stage, this machine shreds plastic waste and then washes and dries it using water tanks.

-

Plastic Dryer: This machine heats and densifies shredded plastic for better production. It can also shred and grind soft plastics like LDPE.

-

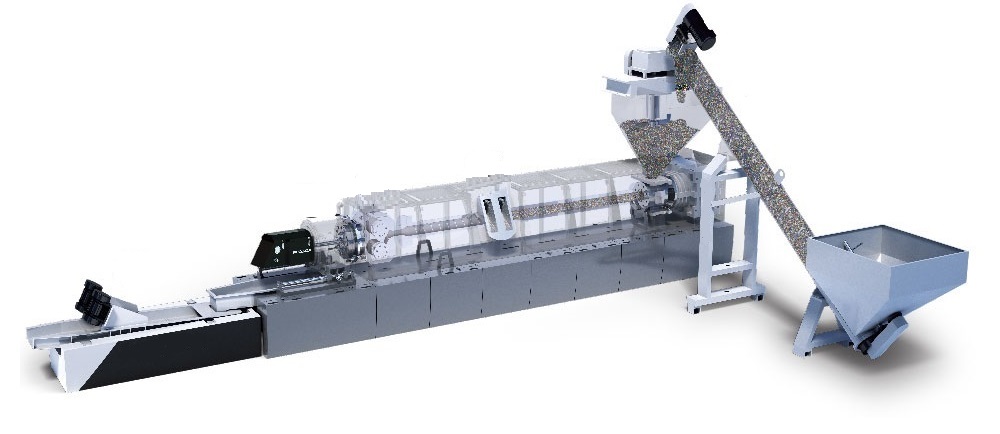

Plastic Granulator: This machine melts shredded plastics and converts them into granules. For more information about granulators, continue reading this article.

-

-

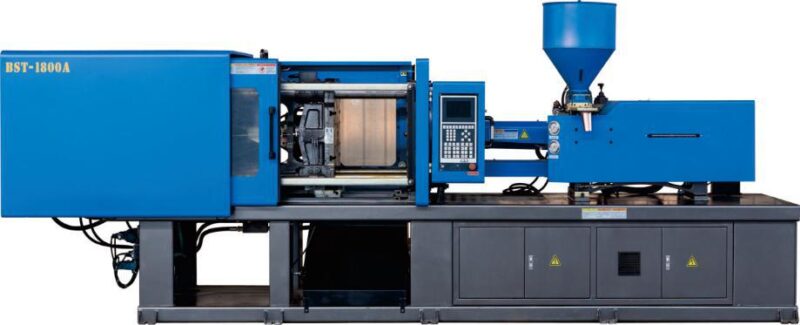

Injection Molding Machine: This machine molds melted plastic into various shapes.

-

Key Considerations for Choosing a Plastic Recycling Machine

-

Type of Plastic Waste: Identify whether the waste is hard or soft, as each type requires a specific machine with appropriate feeding systems and blades.

-

Production Capacity: Choose a machine that matches the volume of plastic waste you have. Recycling machines come in capacities ranging from tens of kilograms to several tons per hour.

-

Build Quality: The quality of the machine is crucial for durability, efficiency, and product quality. Opt for reputable manufacturers that offer reliable after-sales service and warranties.

-

Technology and Equipment: Up-to-date technology is key for efficiency and product quality. Consider machines with precise control systems, effective filtration, cooling systems, and good insulation.

-

Price and After-Sales Support: Prices depend on factors like type, capacity, quality, and manufacturer. Compare prices and check the after-sales services offered by different companies to make an informed decision

Benefits of Using a Plastic Recycling Machine

-

Reduced Natural Resource Consumption: Recycling plastic decreases the need for extracting new raw materials like oil and gas.

-

Decreased Environmental Pollution: It prevents the accumulation of plastic waste in the environment, reducing soil and water pollution.

-

Energy Savings: Recycling plastic significantly saves energy compared to producing plastic from new raw materials.

-

Job Creation: The plastic recycling industry generates new job opportunities in collection, sorting, processing, and producing new products from recycled plastic.

Applications of Plastic Recycling Machines

-

Production of New Products: Recycled plastic can be used to manufacture a variety of new products, such as bottles, containers, pipes, bags, and furniture.

-

Construction Industry: Recycled plastic can be used to create building materials like blocks, bricks, and asphalt.

-

Textile Industry: Recycled plastic can also be processed into fibers and textiles.

Price Factors for Plastic Recycling Machines

-

Type of Machine:

- Shredders

- Washing machines

- Granulators

-

Production Capacity: The price varies significantly depending on the machine’s capacity, with larger machines costing more.

-

Type of Plastic: Different plastics require specific machines and blades, so choose according to the plastic grade. For example, a machine for recycling plastic bottles differs greatly from others.

Manufacturer Considerations

Plastic recycling machines are engineered products. Using inferior materials can make machines cheaper, but this often leads to higher maintenance costs and lower output quality. Therefore, do not prioritize price over quality!

Conclusion

Plastic recycling machines are powerful tools for preserving the environment and natural resources. They can transform plastic waste into recycled granules and ultimately into new products. As public awareness increases, infrastructure improves, and new technologies develop, the role of plastic recycling in environmental conservation will likely gro